Terry Lifts has been a reputable name in the lift industry for over 70 years. We design and manufacture a range of home lifts and platform lifts in Cheshire to the highest standards in quality and safety. Every Terry lift is manufactured in Great Britain to the highest standards, giving you complete peace of mind.

In 1988, we were the first to launch the Harmony, a through-floor home lift. Since then, we’ve introduced the Harmony FE and Lifestyle home lifts, and out latest model, the Affinity home lift, a high quality two-person, two-level standing or seated domestic home lift.

For more details about the history of Terry lifts, and why we’re the name to trust, read on…

After two decades of dedicated service and leadership growth within the company, Tim Barrow is appointed Managing Director—marking a new era for Terry Lifts built on experience, innovation, and continuity.

2025

2025

To meet growing demand we expanded our export market into the United States of America and Canada.

2024

2024

Introduced to provide a more compact lift that could easily fit into narrow alcoves and smaller properties, as well as providing the same benefits as the Lifestyle. A standing only lift with a payload of 250kg and is the most compact home lift on the market. It offers a stylish, feature-packed solution to future-proof your home with ease and sophistication.

2024

2024

David Allen replaced Peter Morrey as Managing Director who then became Chairman

2020

2020

A fully-enclosed version of the Harmony range the Harmony FE was introduced to allow standing use and carers to travel with wheelchair users.

Due to its design we were able to increase weight capacity to 325kg and is available in 4 carriage sizes.

2018

2018

Facelift of the Melody 2, named the Melody 3 introduced with improved styling. Both platforms are available in two widths and has an option for either manual or powered gates.

2013 - Present Day

2013 - Present Day

A compact fully enclosed 2-person domestic lift, the Lifestyle.

The Lifestyle was the first corner-fit homelift, improving space within the property.

2012

2012

Initially designed for the Australian market due to its large platform size.

The lift can travel up to and including 1000mm with a payload of 385kg.

2011 - Present Day

2011 - Present Day

A face lift of the Phase 1 Harmony was required. This face lift brought easier installation processes, aesthetic improvements and allowed for a larger carriage size with the same footprint as the Phase 1. Payload ranges from 250kg – 280kg subject to the carriage size.

2009 - Present Day

2009 - Present Day

Hydraulic version of the Classic Melody 2 lifting platform introduced to permit a greater carrying capacity of 500kg, travel to three metres and available in two platform sizes

2007 - 2013

2007 - 2013

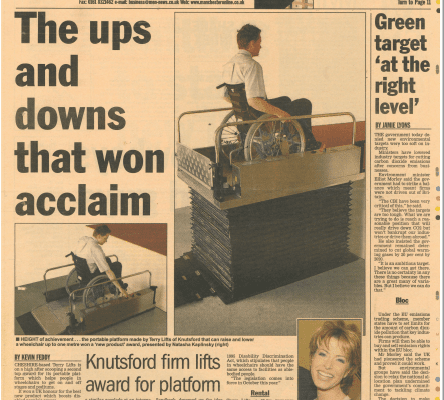

The portable platform lift received The Best Disability product award at Interbuild 2004.

2004

2004

A portable version of the steplift was introduced which won the innovation award at REHA in 2003.

2003

2003

Modular design facilitated the production of several models including the Melody 1, and this system remains the cornerstone of all the Company’s lifts up to one metre travel.

This product allows both wheelchair and ambulant users in both a domestic and public access application. Hydraulically driven up to an including 1000mm travel and has a payload of 250kg and has gates at both landings.

2003 - Present Day

2003 - Present Day

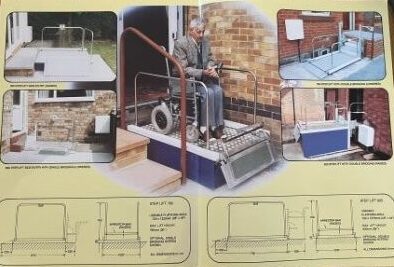

Our Terry Step Lift range includes a low-rise platform lift that travels up to and including 500mm and the TSL 1000 which can travel up to and including 1000mm, both with a payload of 250kg.

Our TSL’s are hydraulically driven and can only be installed into a domestic environment due to safety standards. Both step lifts can have either bridging steps or an upper-level gate and both lifts have a folding ramp to the platform to prevent the wheelchair rolling backwards.

2003 - Present Day

2003 - Present Day

A fully enclosed, heavy duty platform lift aimed more at the commercial market. Had a payload of 500kg with a maximum travel of 4000mm.

2000 - 2010

2000 - 2010

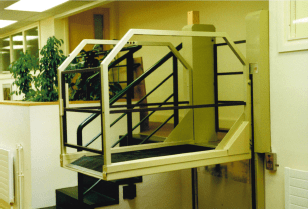

This product superseded the air operated lift and was driven via a hydraulic cylinder. This was the first Terry platform lift to use hydraulics and has proven to be a reliable system which we still use today. The lift had a maximum travel of 1000mm, a payload of 250kg and could be supplied with bridging steps, upper-level gate and was available in special platform sizes for the tightest of locations.

1998 - 2003

1998 - 2003

Expansion necessitated a move to Longridge Trading Estate close by, where the Company remains today

1993

1993

A 2m travel open platform lift was developed and launched as the Melody 2. Driven via a ‘nut and screw’ system providing wheelchair access up to and including 2000mm. Installed in both domestic and public access applications and had a payload of 250kg.

1989 - 2007

1989 - 2007

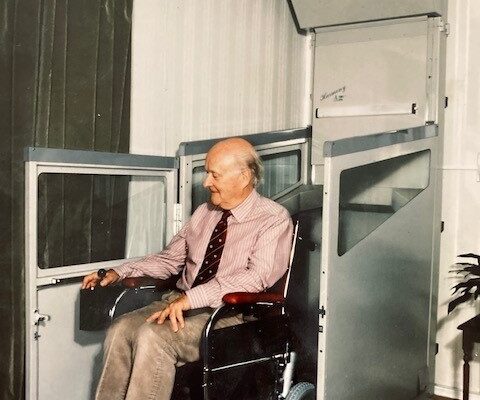

The first domestic through-floor direct acting hydraulic lift on the market, the phase 1 Harmony home lift, launched.

Still our bestselling product to this day and is available in 4 carriage sizes to suit varying end user requirements.

1988 - 2009

1988 - 2009

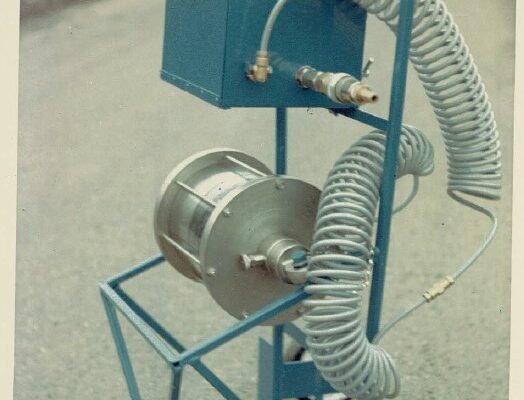

The Pneumatic step lift was air operated by a simple vacuum motor in reverse and an airbag which inflated to raise the platform. The lift was capable of lifting to a maximum travel of 960mm and had a payload of 255kg.

1988 - 1998

1988 - 1998

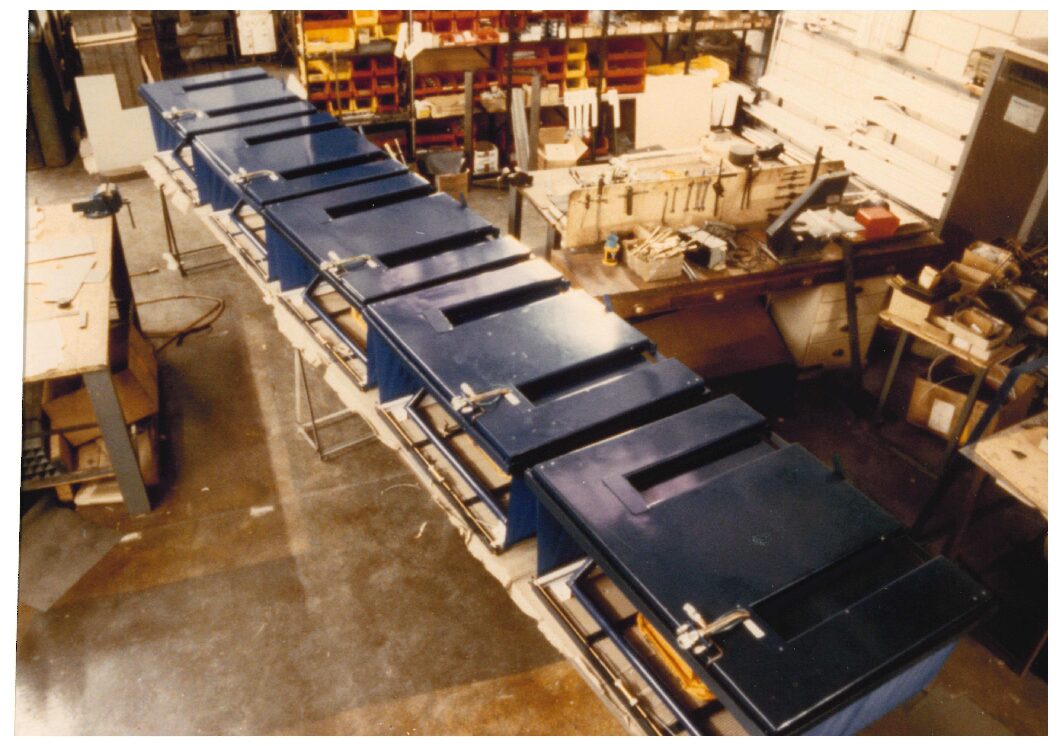

The Company was awarded a contract by IBM to build 35 special lifting workstations for production line computer assembly

1980

1980

The Company outgrew its premises in the centre of Knutsford and bought new premises on the local trading estate

1979

1979

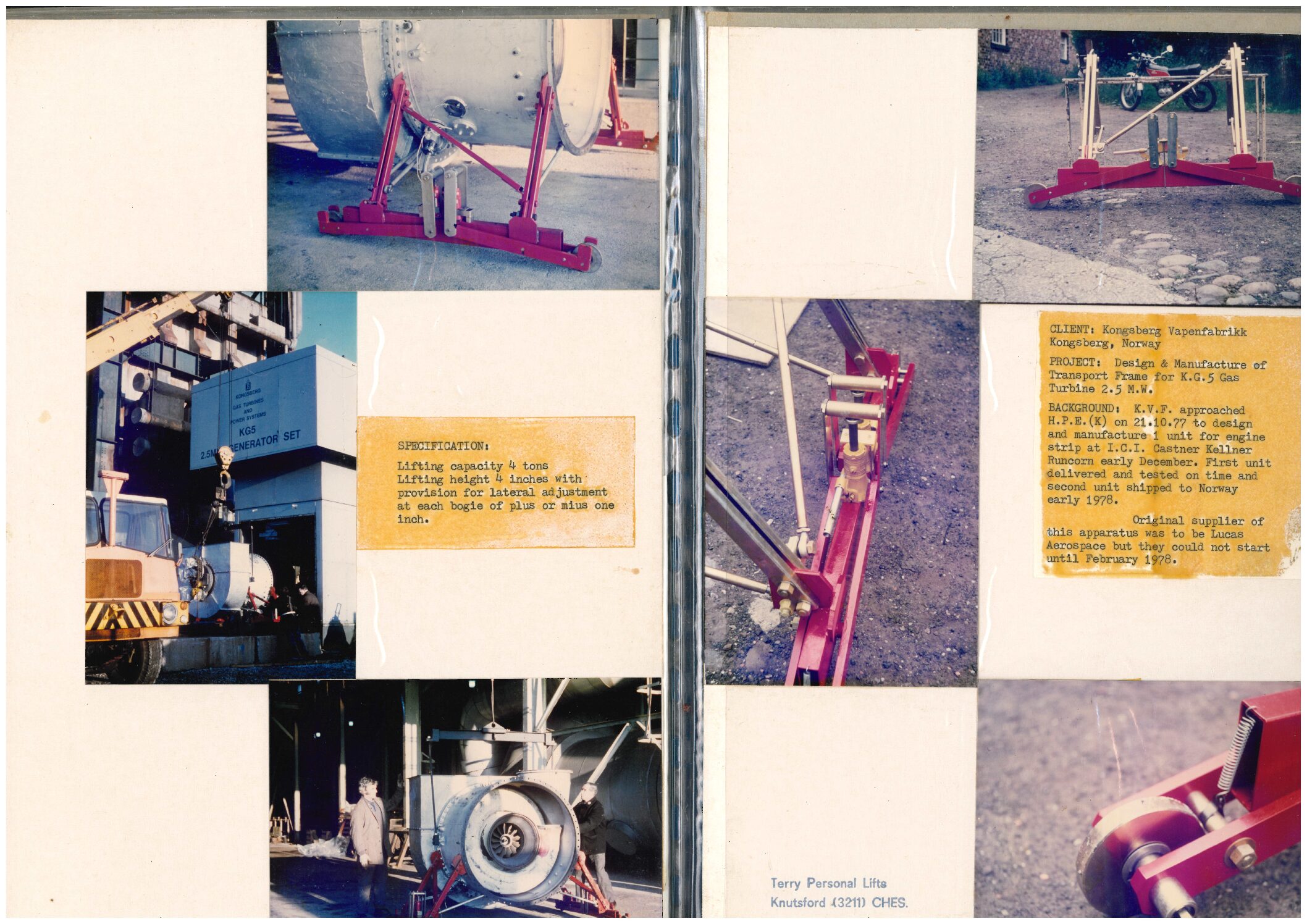

Contract won from Kongsberg Vapenfabrik of Norway to design and build handling/maintenance equipment for their range of gas turbine units

1978

1978

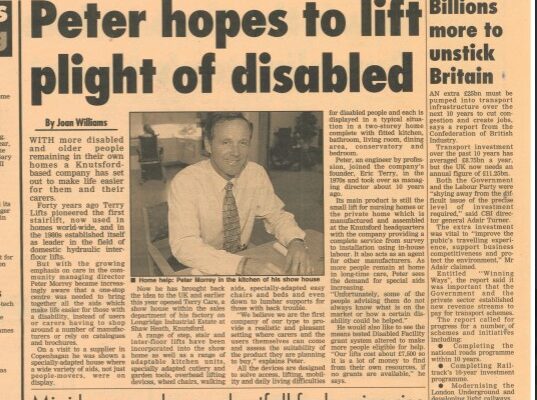

Cheshire Life featured the business in February 1977, detailing Peter’s drive for change, and charting the company’s rising success.

1977

1977

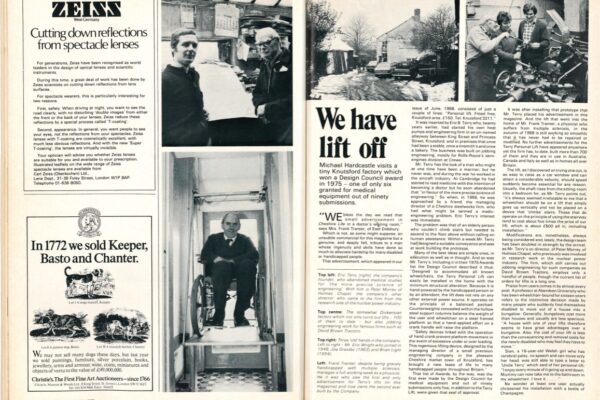

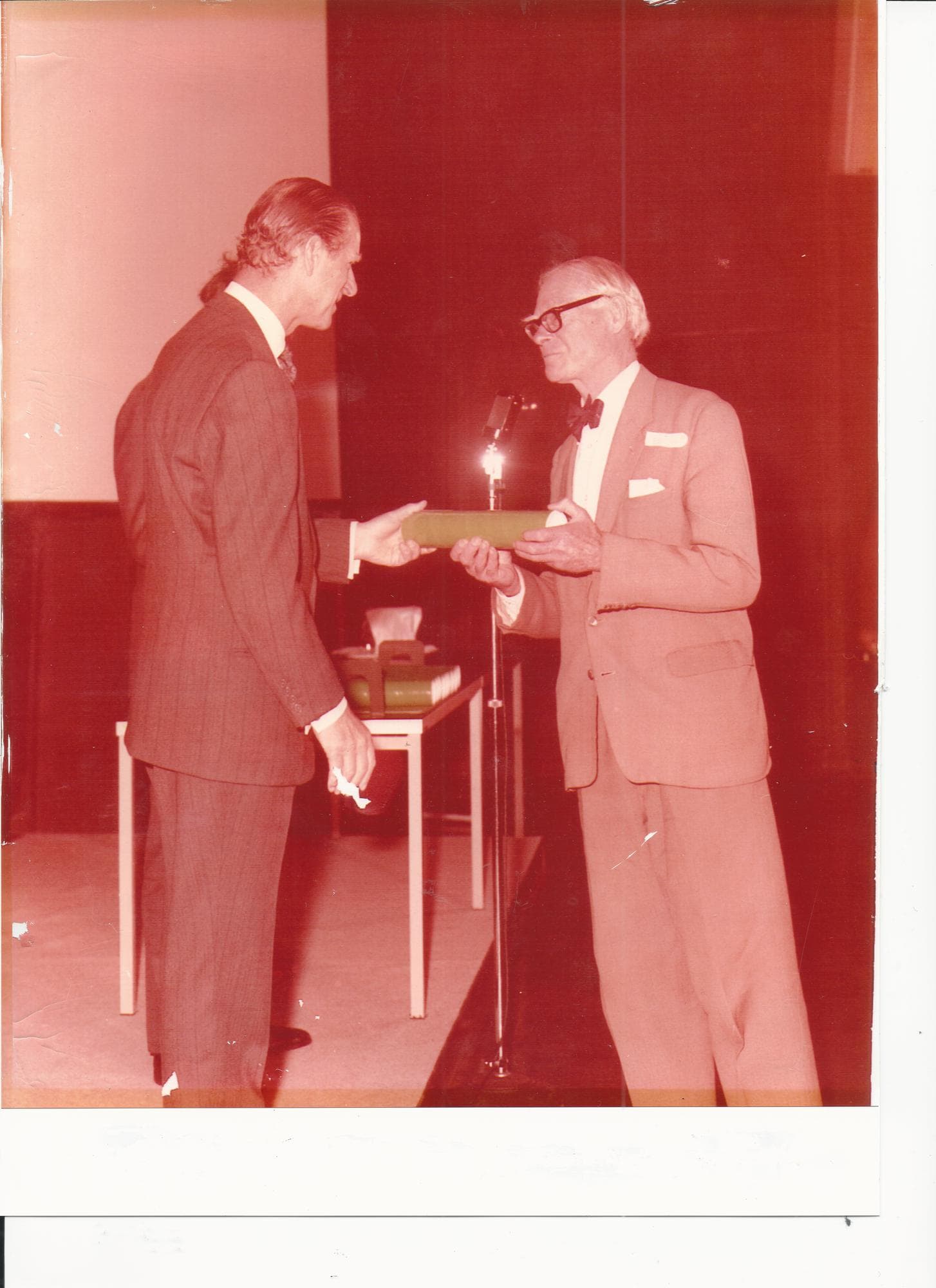

Terry Lifts were awarded the Design Council award for medical equipment for the design and development of the Terry Personal lift

1975

1975

Current owner and company Chairman, Peter Morrey joins the company as general manager.

1972

1972

Contract awarded by Rolls Royce to design and build manipulators to allow the RB211 engines in the Lockheed Tristar to be built and stripped ‘on the wing’

1970

1970

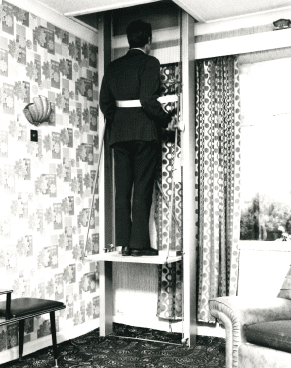

The first counterbalanced stairlift was installed, which led to the development of the Terry Personal hand operated through the floor lift in 1969. The later model included the option for an electric drive unit for users that had limited mobility where hand winding proved to be difficult.

The TPL can be seen in our showroom in Knutsford.

1968

1968

The workshop relocated to the centre of Knutsford

1948

1948

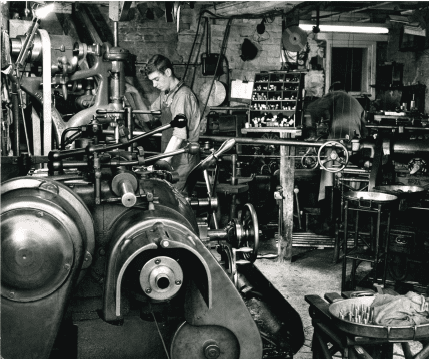

Eric Terry set up a small engineering shop in Bucklow Hill, Knutsford to carry out subcontract engineering work for companies in the Manchester area

1947

1947

*Parts and Labour

Proudly Designed and

Manufactured in Britain

Member of LEIA (Lifts

& Escalator Industry Association)

Sign up to our mailing list to receive up to date information and the latest news.